1. Laboratory Standard Test Methods

(1) DIN Abrasion Test (ISO 4649 Standard)

Principle: By friction between a rotating abrasive wheel (silicon carbide sandpaper or abrasive) and a shoe sole sample, the abrasion volume or mass loss is measured at a certain number of revolutions. The smaller the value, the better the abrasion resistance.

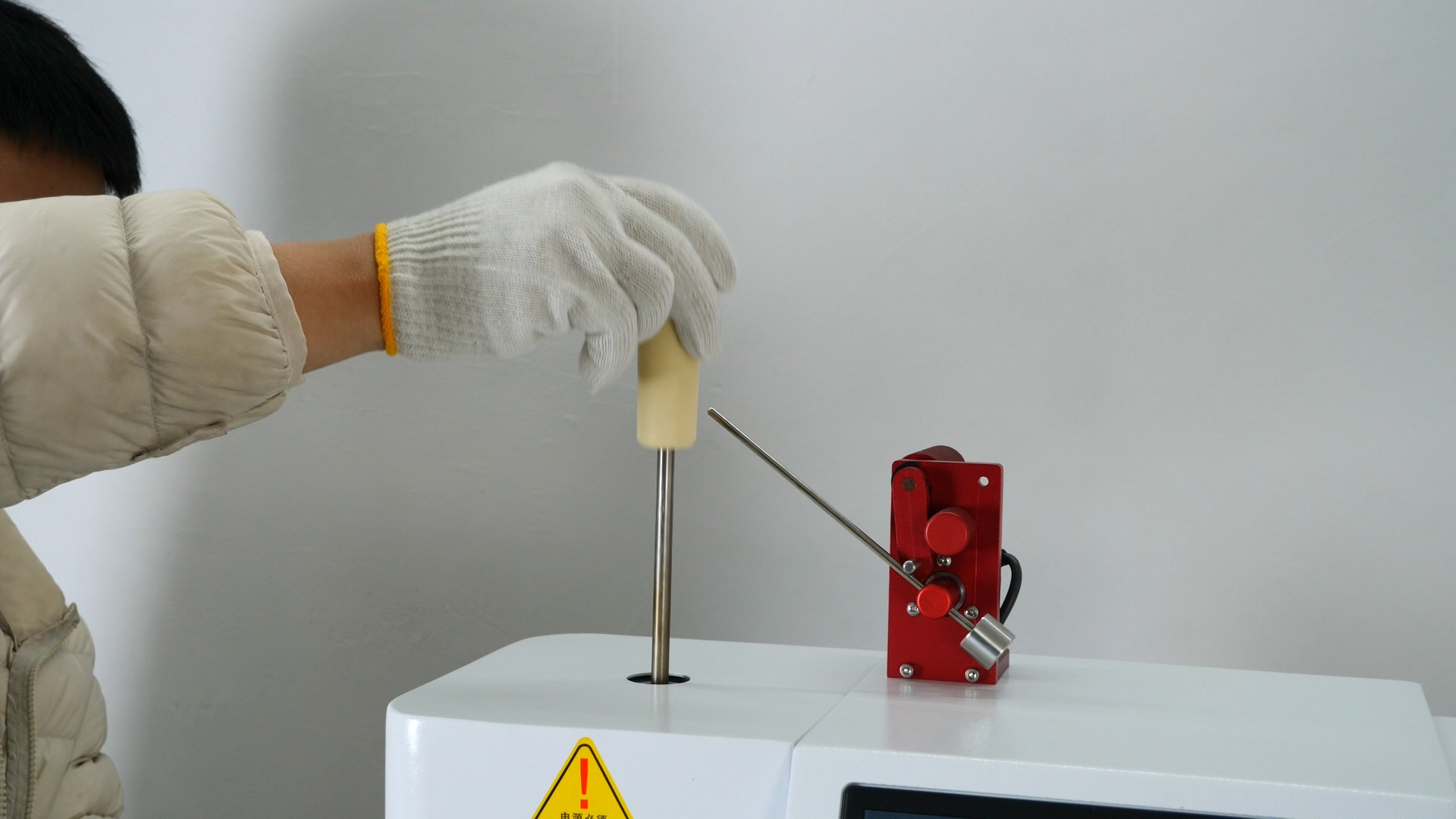

Equipment: DIN abrasion tester.

Operational Steps:

Prepare the shoe sole material into standard samples (e.g., a cylindrical sample with a diameter of 16 mm).

Set the abrasive wheel speed (typically 40–50 revolutions per minute), load (e.g., 5 N or 10 N), and friction distance.

After testing, weigh the sample to determine mass loss, or calculate abrasion volume directly using the instrument.

Application: Suitable for comparing the abrasion resistance of shoe sole raw materials (e.g., rubber, polyurethane, etc.), this is a commonly used industry standard.

(2) Akron Abrasion Test (ISO 4662 Standard)

Principle: The sample is fixed to a rotating wheel and rubs against sandpaper at a certain angle (typically 15° or 30°). The number of revolutions required to achieve the specified thickness or mass loss is measured.

Equipment: Akron abrasion tester.

Operational Steps:

Prepare dumbbell-shaped or circular test specimens and record the initial thickness and mass.

Set the rotational speed (e.g., 76 revolutions per minute), load (e.g., 2.75 N), and friction angle.

After testing, calculate the wear amount (e.g., volume loss/mm³) or wear index (compared to standard rubber).

Features: Simulates the bending friction scenario of shoe soles, with results more closely resembling actual wear and tear during use.

2. Actual scenario simulation testing

(1) Walking test (field test)

Method:

Manual walking: Have testers walk a certain distance (e.g., 50 kilometers) wearing the sole samples on specific road surfaces (e.g., concrete, asphalt, cobblestone), and periodically observe the degree of sole wear (e.g., changes in tread depth, material damage).

Mechanical Walking: Use a gait simulator (e.g., Friction Tester) to fix the sole and simulate the bending, friction, and impact forces experienced during human walking, recording wear data.

Advantages: Closest to real-world usage scenarios, enabling a comprehensive assessment of the sole's overall durability.

(2) Friction coefficient and wear combination test

Principle: While measuring the friction coefficient of the sole, record the material loss during the friction process to evaluate the balance between wear resistance and slip resistance.

Equipment: Friction and wear testing machine (such as James Heal friction tester).

Application: Suitable for sports shoes, safety shoes, and other scenarios that require both slip resistance and wear resistance.

3. Other auxiliary testing methods

(1) Hardness testing (Shore hardness tester)

Correlation logic: Rubber hardness is typically positively correlated with abrasion resistance (higher hardness may indicate better abrasion resistance, but elasticity may decrease).

Procedure: Measure the hardness of the sole material using a Shore hardness tester (e.g., Shore A or D type), and analyze the correlation with abrasion test results.

(2) Microscopic Observation

Method: Observe the microscopic structure of the sole surface (e.g., cracks, material peeling) before and after testing using an electron microscope or optical microscope to assess wear mechanisms (e.g., fatigue wear, abrasive wear).

(3) Accelerated Aging Test

Purpose: Simulate the effects of long-term use or environmental aging (e.g., high temperature, UV radiation) on abrasion resistance.

Equipment: Aging chamber, UV aging tester, combined with abrasion testing to compare performance changes before and after aging.

4. Test Result Analysis and Standards

Key Indicators:

Abrasion Volume (mm³/1.61 km): The lower the value, the better the abrasion resistance.

Abrasion Index: Compared to standard rubber (e.g., NR natural rubber), an index >100 indicates superior abrasion resistance.

Industry Reference Standards:

Sports Shoes: Abrasion volume is typically required to be <100 mm³/1.61 km (DIN test).

Safety Shoes: Must pass specific abrasion tests (e.g., GB 21148-2020 standard) to ensure durability in harsh environments.

5. Notes

Sample Preparation: Samples must be taken from different parts of the sole (e.g., forefoot, heel) to avoid uneven material affecting the results.

Environmental Control: Test temperature (23±2°C) and humidity (50±5%) must be standardized to avoid environmental interference.

Combination of Methods: A single test cannot comprehensively evaluate abrasion resistance; it is recommended to combine laboratory testing with real-world scenario simulations to comprehensively assess sole performance.

Through the above methods, the abrasion resistance of rubber soles can be systematically evaluated, providing a basis for material R&D, production quality control, and product selection.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com