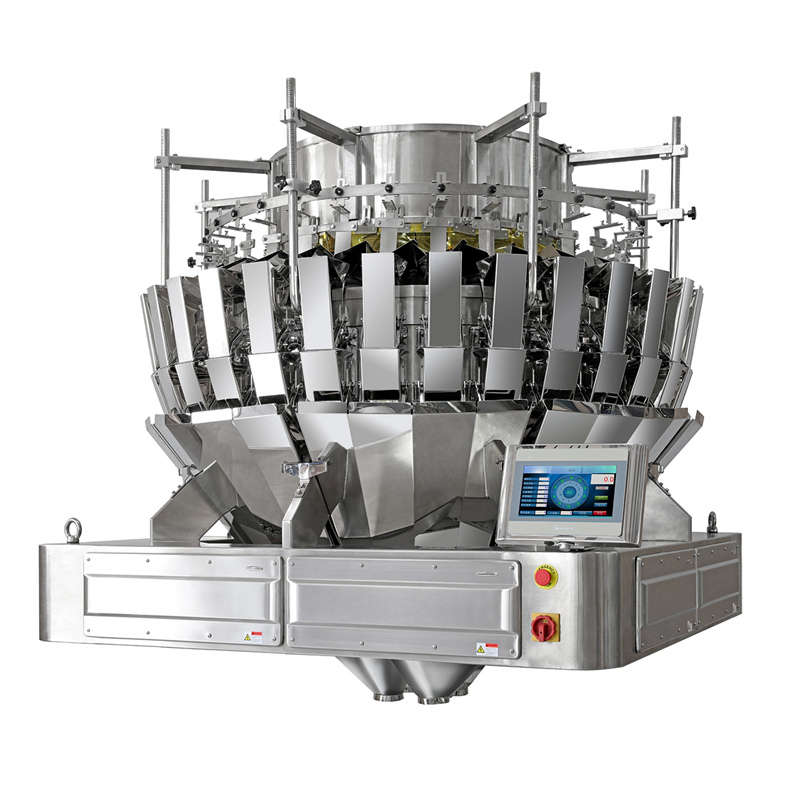

In the fast-paced world of food and consumer goods production, the demand for efficient, accurate, and versatile weighing solutions has never been higher. Especially when it comes to mixed products—from trail mixes and breakfast cereals to confectionery assortments—manufacturers face the unique challenge of handling multiple ingredients while maintaining precision and speed. That's where UUPAC's High-Speed Mixing 32-Head Combination Weigher comes into play. It's designed to elevate your mixed product packaging line.

- Why Choose a 32-Head Combination Weigher for Mixed Products?

Mixed products, such as oatmeal blends, mixed nuts, or snack assortments, require a weighing system that can handle multiple ingredients simultaneously without compromising on accuracy or throughput. Traditional single-head weighers or manual weighing methods fall short in this scenario, often leading to inconsistent portioning, slower production rates, and increased product waste.

UUPAC's 32-Head Combination Weigher is engineered specifically to solve these challenges. It’s the ideal solution for businesses looking to streamline their mixed product packaging process. Whether you’re handling 2-in-1, 3-in-1, 4-in-1, or even 5-in-1 ingredient blends, this weigher delivers unmatched performance.

- Key Features of UUPAC's 32-Head Weigher for Mixed Ingredient Blends

1. Multi-Product Mixing Capability: Supports up to 5-in-1 product mixing, making it perfect for a wide range of blended products. Whether you're combining different nuts, grains, or candies, this weigher handles it all with ease.

2. High-Precision Load Cells: Equipped with special high-precision load cells that deliver accuracy within ±0.1g, even when handling small doses (5-250g per hopper for the TY-A-M/P32-5 model). This level of precision is critical for maintaining product quality and meeting regulatory standards.

3. High-Speed Stagger Dump Function: Boosts throughput with its efficient dumping mechanism, ensuring that your production line keeps up with high-demand schedules. The max weighing speed for mixed products reaches an impressive 60 packs per minute, significantly increasing your overall productivity.

4. Modular & CAN Bus Technology: Enhances operational efficiency and stability. The modular design simplifies maintenance and upgrades, while CAN bus technology ensures seamless communication between components, reducing downtime and improving reliability.

5. Dual-Product Upper Storage Funnel: The upper storage funnel is divided to handle two different products simultaneously, streamlining the mixing process and reducing the need for additional equipment.

6. Independent Main Vibrator: Allows precise control over the thickness of product flow, ensuring that each ingredient is fed into the weighing hoppers at the optimal rate—critical for preventing jams and maintaining consistency.

7. Sturdy & Stable Construction: The integral machine frame and cabinet provide exceptional stability, minimizing mechanical vibration and further enhancing weighing accuracy.

- Ideal Applications for UUPAC's 32-Head Combination Weigher

This 32-head combination weigher is a versatile workhorse, perfect for a range of mixed products across industries:

1. Food & Beverage: Oatmeal blends, mixed nuts, trail mixes, breakfast cereals, and snack assortments.

2. Confectionery: Mixed candies, chocolate assortments, and gummy combinations.

3. Pet Food: Small-batch mixed pet treats with precise ingredient portions.

Its ability to handle products with good fluidity makes it a go-to solution for manufacturers looking to expand their mixed product offerings without sacrificing efficiency.

- Why choose UUPAC's 32-Head Combination Weigher?

UUPAC has a reputation for delivering innovative, reliable automation solutions for the packaging industry. Our 32-Head Combination Weigher is the result of years of research and development, designed to address the unique challenges of mixed product weighing. With features that prioritize accuracy, speed, and flexibility, it's more than just a machine—it's an investment in your production line's efficiency and profitability.

Ready to take your mixed product packaging to the next level? Contact us today to learn how UUPAC's 32-Head Combination Weigher can integrate seamlessly into your existing setup and help you meet your production goals.