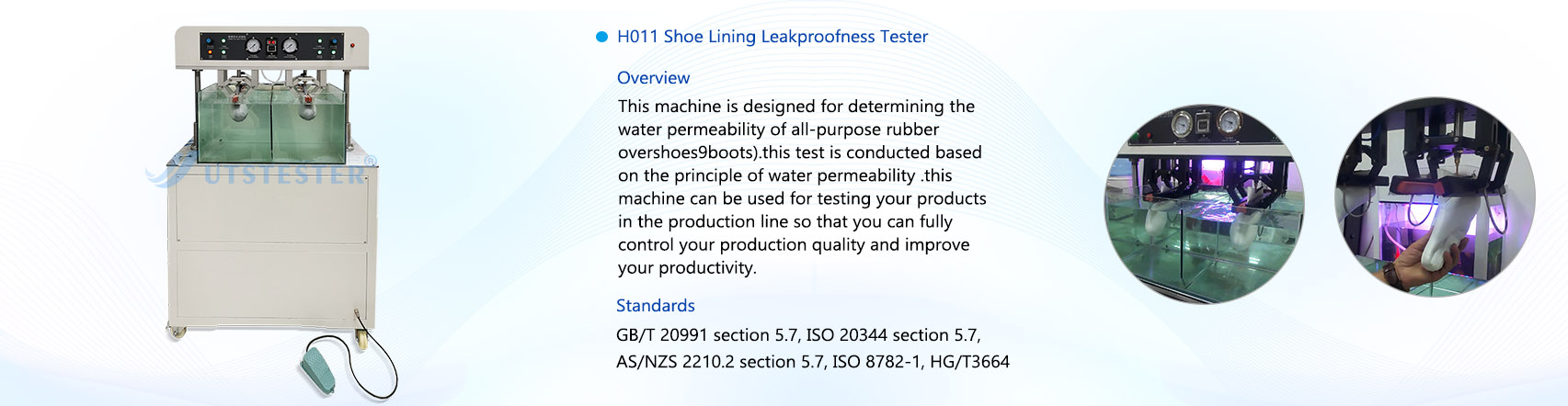

Product Name: Shoe Lining Water Permeability Tester/Shoe Lining Waterproof Tester

Sock cover waterproof testing is a critical step in evaluating the water resistance of sock covers (such as splash resistance, water seepage resistance, and water pressure resistance). It is widely used in quality inspection for sock cover products in outdoor, medical, and industrial protective scenarios.

1. Product Description:

The shoe lining water resistance tester rapidly detects whether rubber-soled shoes and inner linings are waterproof. This machine can be integrated into production lines for 100% inspection of finished products, ensuring comprehensive control over waterproof quality. During testing, the machine's pneumatic fixture seals the test specimen and submerges it in water while simultaneously injecting pressurized air. Any water ingress immediately produces bubbles. Upon reaching the preset test duration, the fixture automatically floats the specimen to the surface.

2. Test Methods:

Inflation Method: Seal the shoe opening. Fill the sealed shoe cavity with compressed air at a specified pressure, then submerge the shoe in a water tank. Maintain the water level within 75mm of the shoe opening. After a specified duration, inspect the shoe surface for bubbles.

Immersion Method: Submerge the shoe in water, maintaining the water level within 75mm of the shoe opening. After a specified immersion period, remove the shoe and inspect for water ingress.

Compliant Standards: GB/T 20991 Section 5.7, ISO 20344 Section 5.7, AS/NZS 2210.2 Section 5.7, ISO 8782-1, HG/T3664

3. Specifications for Shoe Lining Water Resistance Tester:

Clamp Face Length: 220mm

Simultaneous Testing Capacity: 2 pieces (4 pieces can also be accommodated)

Fixture lifting stroke: 320mm

Inflation pressure: 0~50kPa or (air compressor provided by customer)

Water tank dimensions: 42×42×32cm

Timer: LED, 0~99999999 seconds

Dimensions: 93×50×150cm

Weight: 130kg

Power supply: 1∮, AC220V, 3A

4. Sample preparation:

(1) Samples shall be drawn from batches of finished shoes (boots).

(2) Sample quantity: At least three pairs per group.

(3) Standardized sample conditions: Samples shall be conditioned for at least 24 hours prior to testing at 23°C and 60% relative humidity.

Machine Structure: Consists of motor, clamping device, control panel, pneumatic system, water tank, and main housing assembly

5. Result Evaluation:

(1) When testing by inflation method: Observe whether bubbles emerge from the shoe upper

(2) When testing by immersion method: Observe whether water penetrates into the shoe

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com